- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

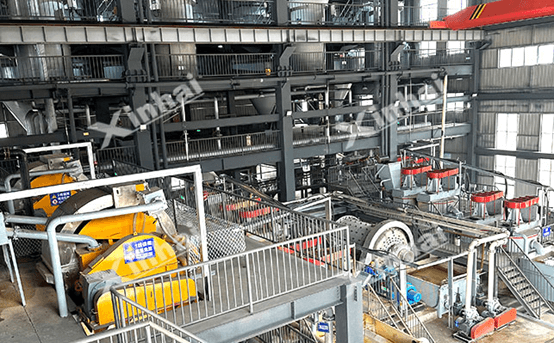

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Unlocking the Value: A Comprehensive Guide to Manganese Ore Processing

2025-03-06 XinHai Views (637)Manganese is found in various forms of ores, the main ones are manganese oxide, manganese carbonate and manganese silicate. It is not only an indispensable raw material in ferrous metallurgy, but also a raw material for batteries, paint dryers, disinfectants and so on. According to the difference in the nature of its ores, they are also different, mainly washing, gravity separation, magnetic separation and flotation are common. However, because our country's manganese is mostly poor, some of the ore only use one method, can not get a more ideal grade of manganese concentrate, it is through several combinations to form a joint beneficiation process. Here we gather together to understand!

1、Manganese oxide ore washing method

Ore washing as a traditional manganese beneficiation method, for rich manganese ore can be directly washed into smelting. In the ore washing process, direct washing is often used, or the ore is washed first and then sent to the vibrating screen for sorting, which generally needs to go through two or three times of washing.

2、Manganese oxide gravity separation method

Manganese oxide gravity sorting mainly uses the density difference between manganese and gangue minerals to sort (generally manganese minerals have a higher density than gangue minerals), there can be two kinds of gravity sorting jigging machine and gravity sorting concentration table, of which the former is more suitable for dealing with large and medium-grained manganese oxide ores; the concentration table is more suitable for dealing with fine or small-grained manganese oxide ores.

However, with the gradual depletion of rich manganese ores, lower grade manganese ores and difficult to select manganese ores, due to the complexity of their ore embedded, target minerals and gangue minerals embedded closely, the use of a single repeated selection can not achieve the desired grade. However, if the dissociation degree between minerals increases, it will lead to the loss of manganese, so for difficult to select manganese, gravity separation and other methods are more commonly used in combination with gravity separation as a pre-selection operation.

3、Magnetic separation of manganese oxide

Magnetic separation of manganese oxide minerals is due to the presence of weakly magnetic minerals in manganese ore, magnetic impurities can be removed by magnetic separation, mainly suitable for processing manganese ore with small particle size. When the operation, strong magnetic magnetic separators (permanent magnetic roller type strong magnetic separator, permanent magnetic high gradient strong magnetic separator, vertical ring high gradient strong magnetic separator) are often used for sorting. Although the magnetic separation method is more expensive in terms of infrastructure investment, the overall consumption is low, and the operation is simple and easier to maintain and control.

4. Manganese oxide flotation method

The characteristic feature of manganese oxide is that the surface of the mineral is easily wetted by water, and the buoyancy is low, so one flotation method is not used for selection, but is often combined with other methods to create a joint beneficiation method.

5、Combined beneficiation method of manganese oxide

According to the nature of manganese oxide ore, the following methods are generally used: gravity separation-magnetic separation and magnetic separation-flotation.

Gravity separation-magnetic separation: For some low-grade manganese oxide, magnetic separation can be adopted and then gravity separation. Magnetic separation adopts roller strong magnetic separator, while gravity separation adopts jigging machine. Although magnetic separation can get high manganese recovery rate, but its concentrate is low. While gravity sorting can get higher concentrate grade, these two processes can complement each other to get more ideal manganese oxide concentrate.

Magnetic separation-flotation method: This combined process is mainly suitable for processing some target manganese oxide minerals. When the ordinary strong magnetic separation, gravity separation, flotation, etc. can not achieve better sorting effect, the selection can be completed by strong magnetic flotation + magnetization roasting. Under the condition of magnetization, the roasting temperature is 900 ℃, after roasting for a certain period of time and cooling, then magnetic separation and flotation operations are carried out to obtain the final manganese oxide concentrate.

The above are some commonly used beneficiation methods for manganese oxide ore. In the actual beneficiation plant, in order to choose the right method and get the ideal return on investment, it is necessary to first conduct the beneficiation test and design a suitable beneficiation method for manganese oxide through testing and analysis, so as to achieve the ideal recovery rate as possible.

Sustainable Mineral Processing Innovations for Eco-Efficient Resource Extraction

As the global energy transition accelerates demand for critical minerals, the extractive sector is undergoing a technological metamorphosis. Three pivotal vectors now define modern mineral processing: precision-driven extraction, circular material management, and integrated digital intelligence. ... [more]

Techniques for Washing Chrome Ore

... [more]

Related Article

- Chrome Ore Beneficiation Solutions from Xinhai – Efficient, Eco-Friendly, and Customized

- Mining Magnetic Separation

- Comprehensive Guide to Chrome Ore Beneficiation Technology

- Chrome Wash Plants: Science, Cost & Regional Insights

- Ball Mill Machine

- What is Lithium Processing Technology

- Mineral Processing Technology

- What are the Technologies for Lithium Production

- Gold Heap Leaching Summery

- How Hard Rock Lithium Processing Works: Mine to Market

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China