- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

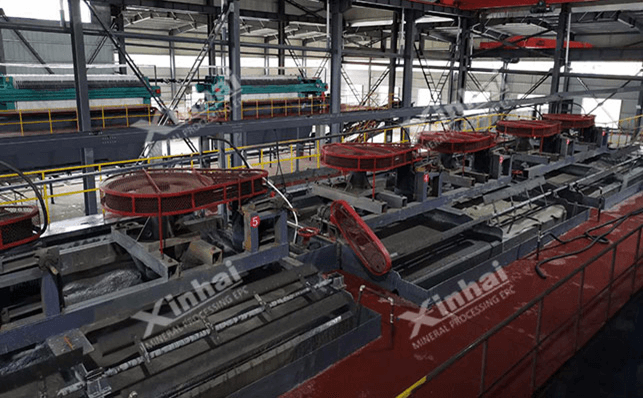

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Silica Sand Processing Guide : Efficient Methods, Equipment & Cost-Saving Tips

2025-03-14 XinHai Views (564)Quartz sand is a common and widely used non-metallic raw material, widely applied in glass, foundry, ceramics, metallurgy, construction, chemical and other industries. Due to the demand for its application areas, the requirements for the disposal of quartz sand in the beneficiation process are high. This paper discusses the process of separating quartz sand from its common gangue minerals. The common gangue minerals in quartz sand include metallic minerals such as hematite, magnetite, limonite and ilmenite, as well as non-metallic minerals dominated by feldspars. In the following, we will introduce the process of completing these two parts:

1. Processes for Separating Quartz Sand from Metallic Minerals with a Predominance of Iron Minerals

Iron is a common harmful impurity in quartz sand, and it is present in quartz sand in a total of the following forms:

(1) Present in clays and kaolinized feldspars;

(2) Adheres to the surface of quartz grains to form an iron hydroxide film;

(3) Present in heavy mineral impurities such as ilmenite;

(4) Present in quartz grains as impregnation or penetration;

(5) In grains of minerals such as mica and hornblend.

Due to the presence of iron impurities in a more complex form, its separation process is also more diverse and mainly includes the following types:

(1) Scrubbing method

The scrubbing method uses mechanical force and mutual abrasion between mineral particles to remove the iron film from the surface of quartz sand, as well as the adhesive impurities of quartz sand minerals, but can also remove part of the iron minerals in clay feldspar. In this method, the factors that have a greater impact on the cleaning effect are the design features and configuration shape of the scrubber itself, the cleaning time and the cleaning concentration. The selection of scrubbing equipment should be determined according to the nature of the quartz sand ore after testing. The scrubbing concentration is generally controlled at 50%-60%, and the scrubbing time depends on the quality requirements of the raw material, which should be determined based on testing.

(2) Magnetic Separation

Magnetic separation is mainly used to remove minerals such as hematite, limonite, magnetite and smectite. When the iron impurity content of quartz sand is low, wet strong magnetic separator is generally used for sorting. The more important influencing factor is the fineness of the minerals to be selected, generally the finer the mineral grains of quartz sand, the better the effect of separating iron impurities.

(3) Gravity Separation

Gravity separation removes heavy minerals from quartz sand, mainly ilmenite whose density is greater than 2.9g/cm3. Spiral flumes are often used as gravity separation equipment for quartz sand.

(4) Flotation Method

The flotation method can be divided into two processes: separate iron-mica flotation and combined iron-mica flotation. These two methods use different reagent application modes, mainly petroleum sulfonates and pine oils combined with iron flotation and sulfuric acid as a slurry conditioner.

(5) Microbial Leaching

In addition to these three traditional beneficiation methods, microbial leaching is also a method that can remove the thin iron film on the surface of quartz. Microorganisms such as Aspergillus niger, Penicillium and others are mainly used for soaking them, but this technology has not yet been applied to large-scale industrial production.

2. Separation Process of Quartz Sand and Non-Metallic Minerals Based on Feldspar

Quartz sand is close in nature to non-metallic minerals such as feldspar and clay, so it is difficult to separate feldspar from quartz sand. The removal of feldspar impurities is generally carried out by washing and sorting desliming, flotation and acid leaching.

(1) Washing and Classifying Desliming

For quartz sand containing a large amount of clay minerals, washing and desliming is an effective way to remove clay, generally adopted in quartz sand before separation as a preparatory work for removing impurities and cleaning.

(2) Flotation Method

The flotation process of quartz sand can be divided into fluorinated flotation and non-fluorinated flotation. Fluoridated flotation is a separation method using a cationic collector and hydrofluoric acid as an activator. In fluoride-free flotation, sulfuric or hydrochloric acid is used as a feldspar activator, and a suitable trap is used to separate the feldspar. Under the same conditions, flotation results using hydrochloric acid as an activator were better than using sulfuric acid as an activator.

Processing Quartz Ore for High-Purity Applications: Techniques, Challenges, and Industry Impact

As a mining professional with years in the field, I’ve seen firsthand how the journey from raw quartz ore to ultra-pure SiO₂ shapes everything from cost to environmental impact. Here’s how it’s done, why it matters, and what lies ahead.... [more]

How Hydrocyclones Improve Efficiency in Gold Mining

Among the unsung heroes of modern mineral processing, hydrocyclones stand out as powerful tools that streamline operations and boost recovery. ... [more]

Related Article

- Chrome Ore Beneficiation Solutions from Xinhai – Efficient, Eco-Friendly, and Customized

- Mining Magnetic Separation

- Comprehensive Guide to Chrome Ore Beneficiation Technology

- Chrome Wash Plants: Science, Cost & Regional Insights

- Ball Mill Machine

- What is Lithium Processing Technology

- Mineral Processing Technology

- What are the Technologies for Lithium Production

- Gold Heap Leaching Summery

- How Hard Rock Lithium Processing Works: Mine to Market

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China