- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

Home Product Gold Extraction Equipment Leaching Agitation Tank

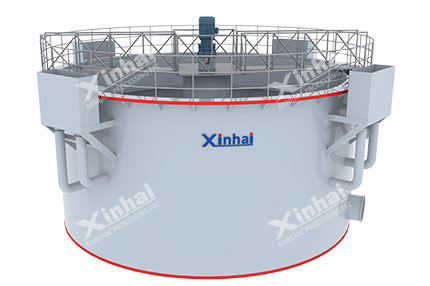

Leaching Agitation Tank

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Entering leaching tank via hollow shaft, air is agitated and dispersed by rotation of impellers.

The two new type impellers with large diameter, low speed and low power consumption, which can reduce the wear of carbon.

The moderate stirring intensity, pulp concentration and fineness distributes consistently can improve the adsorption rate and import rate.

【Product Structure】

With dual impellers rotating and agitating, ore pulps move downward and then diffuse along damping plate. Air is fed in tank from the lower end of shaft, and blended with ore pulps to form uniform suspending mixed liquid. In the gold cyaniding process, leaching agitation tank is applied to leach and carbon-absorb ore pulps whose fineness is -200 meshes and whose density is less than 45%. Under similar circumstance, it is also applied to agitation and leaching in metallurgy, chemical and light industry.

【Technical Parameters】

| Model | Tank Spec. (DX H) (mm) |

Effective Volume (m3) |

Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model |

Motor Power (kW) |

Reducer Model | Tank Weight (kg) |

Total Weight (kg) |

| SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0X3.0 | 3000X3000 | 19 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3X3.15 | 3000X3150 | 20 | 3480 | 4160.6 | |||||

| SJ3X3.5 | 3000X3500 | 22.97 | 3211 | 4334.6 | |||||

| SJ3.15X3.55 | 3150X3550 | 25.73 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 1310 | Y132S-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5X4 | 3500X4000 | 35.6 | 4230 | 5429 | |||||

| SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | 4 | XLD4-5-35 | 4260 | 5025 | ||

| SJ3.7X4.2 | 3700X4200 | 42 | 42 | Y112M-4 | XLD4-5-43 | 5266 | 6153 | ||

| SJ4.0X4.5 | 4000 X4500 | 52.78 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0X6 | 4000 X6000 | 71 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11-4P-44.65-M4 | 7681 | 9200 |

| SJ4.5X5.0 | 4500 X5000 | 74.75 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 2046 | Y160M-4 | 11 | XLD11-8-47 | 8740 | 14291 |

| SJ5.5X6.0 | 5500X6000 | 135.42 | 2100 | 12467 | 18745 | ||||

| SJ6.5X7.0 | 6500X7000 | 215 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22-4P-70.87 | 17890 | 25978 |

| SJ7.0X7.5 | 7000 X7500 | 269 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5X8.0 | 7500 X8000 | 331 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0X8.5 | 8000X8500 | 402 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5X9.0 | 8500X9000 | 480 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |

【Successful case】

A gold processing plant in Shanxi was built in 2010, the capacity is 200 t/d, and adopted direct cyanide——zinc dust precipitation process. Due to the stirrer paddle of previously installed double impeller agitation tank is a bit small, the speed is low and pulp agitator is uneven, which are against gold leaching. Then Xinhai contracted its cyanide process. Xinhai updated equipment with larger stirring paddle, and added breath prevention device at the bottom of the hollow shaft. Because the excellent ventilation in center and even agitation of sodium cyanide, the gold leaching rate increased from 94.28% to 97.14%.

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China