- Home

- About

-

Mineral Processing EPC+M+O

Providing optimized solutions for your mine, one-stop service for mineral processing plant!

View details -

Product

- Grinding

- Classifying

Grinding & Classifying

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Gold Extraction Equipment

- Washing Equipment

Separating Process

- Thickening

- Dewatering Machine

Thickening & Dewatering

- Accessories

- Auxiliary Product

Consumables

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. View details

-

Solutions

- Gold Tailings

- Tailings

Tailings

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. View details

- Case

-

News

- Contact

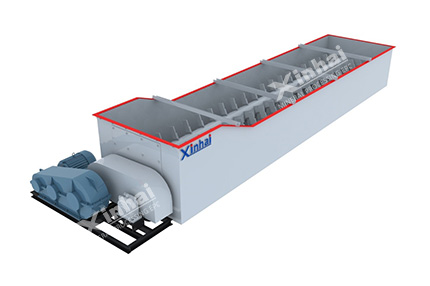

Spiral Chute Washer

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Xinhai spiral chute washer has the characteristics of simple structure, easy installation, low power consumption, easy operation, low manufacturing cost and good desliming effect. Under the agitation of double-row blades on the screw shaft of the washer, the ore cemented by the clay can achieve the slime separation with the good desliming effect.

【Product Structure】

The double spiral chute washer is composed of a tank body, left and right spiral blade shaft and transmission device. The motor drives the two spiral shafts to produce the relative rotation through the reducer, big and small gears. The blades on the spiral shafts are stagger installation. The material is fed from the lower part of the tank body into the middle of two spiral shafts. The mud mass and the ore particles adhering to the surface of the mud are washed by the high-pressure water fed from the upper part of the tank body according to the blade rubbing and scrubbing, so that the ore mud can be broken and the ore particles are separated. The washed fine mud is discharged by the overflow outlet that installed at the back of the tank body, and the scrubbed ore is transported to the ore outlet at the front of the tank through the rotating spiral blade shaft, and then discharge.

【Technical Parameters】

| Model | Lengthe of body(mm) | Width of body(mm) | Production capacity(t/h) | Feed size(mm) | Inclination | Pitch(mm) | Motor | Weight(kg) | |

| Model | Power(kW) | ||||||||

| CXK1566 | 6660 | 1500 | 35-40 | <75 | 10.84° | 300 | Y200L2-6 | 22 | 15800 |

| CXK1676 | 7630 | 1600 | 40-50 | 10° | Y250M-6 | 37 | 17168 | ||

【Successful case】

In an iron and phosphorus polymetallic ore dressing project, there were a lot of mud on the surface of ore, which interfered with the separation and purification of apatite, magnetite and other minerals. For this reason, Xinhai used the spiral chute washer to wash and desilt the minerals. Finally, the desliming effect was remarkable, which effectively ensured the separation and purification of minerals.

【Related knowledge】

- To Eliminate The Hidden Dangers And Build A Strong Line of Security, Xinhai Mining Is Acting!

- What Xinhai wear-resistant rubber linears can provide for you?

- Design and cost control of Xinhai one-stop service for mineral processing plant

- Ball Mill Maintenance and Repair Method

- Wet Energy-saving Rod Mill

- 700t/D Gold Processing EPC Project of Alitimad in Sudan

- A Big Inventory of Quartz Sand Processing Equipment,Collect It!

- Comprehensive Analysis of CIP in Gold Processing

【Related products】

Leave Message

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing EPC

Solutions

CONTACT US

- Tel: 0086 15901320633

- Fax: 0086 10 59621207

- Email: mhxu@xinhaimining.net

© 2017 Shandong Xinhai Mining Technology & Equipment Inc. Technical Support: Beijing Xinhulian Technology Co., Ltd.

Factory Address: No. 188, Xinhai Street, Fushan high-tech industrial development district, Yantai, Shandong, China